In the oil and natural gas industry, gas processing and gas conditioning are often used interchangeably. While the two are related concepts and have similar processes, they can have different objectives in the production and distribution of natural gas. In this blog, we will go through the similarities and differences between the two.

What is Gas Processing?

Gas processing is a very important step in the production and distribution of natural gas. When natural gas is obtained in its natural form, it contains impurities such as carbon dioxide, hydrogen sulfide, water vapour and other contaminants. The gas processing industry subjects the gas through various stages before the gas can be transported or used.

The following are the stages usually involved in the gas processing industry:

- Separation: The raw gas is separated from other phases

- Dehydration: The water vapor is then removed to keep the pipelines corrosion-free

- Acid Gas Removal: carbon dioxide and Hydrogen Sulfide are removed

- Natural Gas Liquids Recovery: Natural gas liquids such as butane, propane and ethane are extracted for heating and cooking

- Storage and Transportation: The purified gas is then stored in trucks and ships via pipelines to industrial facilities.

What is Gas Conditioning?

Gas Conditioning is a process by which raw and natural gas is prepared to meet specific quality standards for specific purposes and transportation.

Gas Conditioning involves a range of processes and this depends on the composition of gas and specific quality requirements.

The following are a few common techniques that are used in gas conditioning:

- Dehydration: Water vapor is removed from the gas by absorption, adsorption or condensation

- Acid Gas Removal: This process involves removing acid gases such as hydrogen sulfide and carbon dioxide

- Mercury Removal: This technique involves removing trace amounts of mercury

- Compression and Filtration: This process helps in compressing the gas to the required pressure and filters out any solids or liquids present

How does Sungov Engineering contribute to the Gas Conditioning Process?

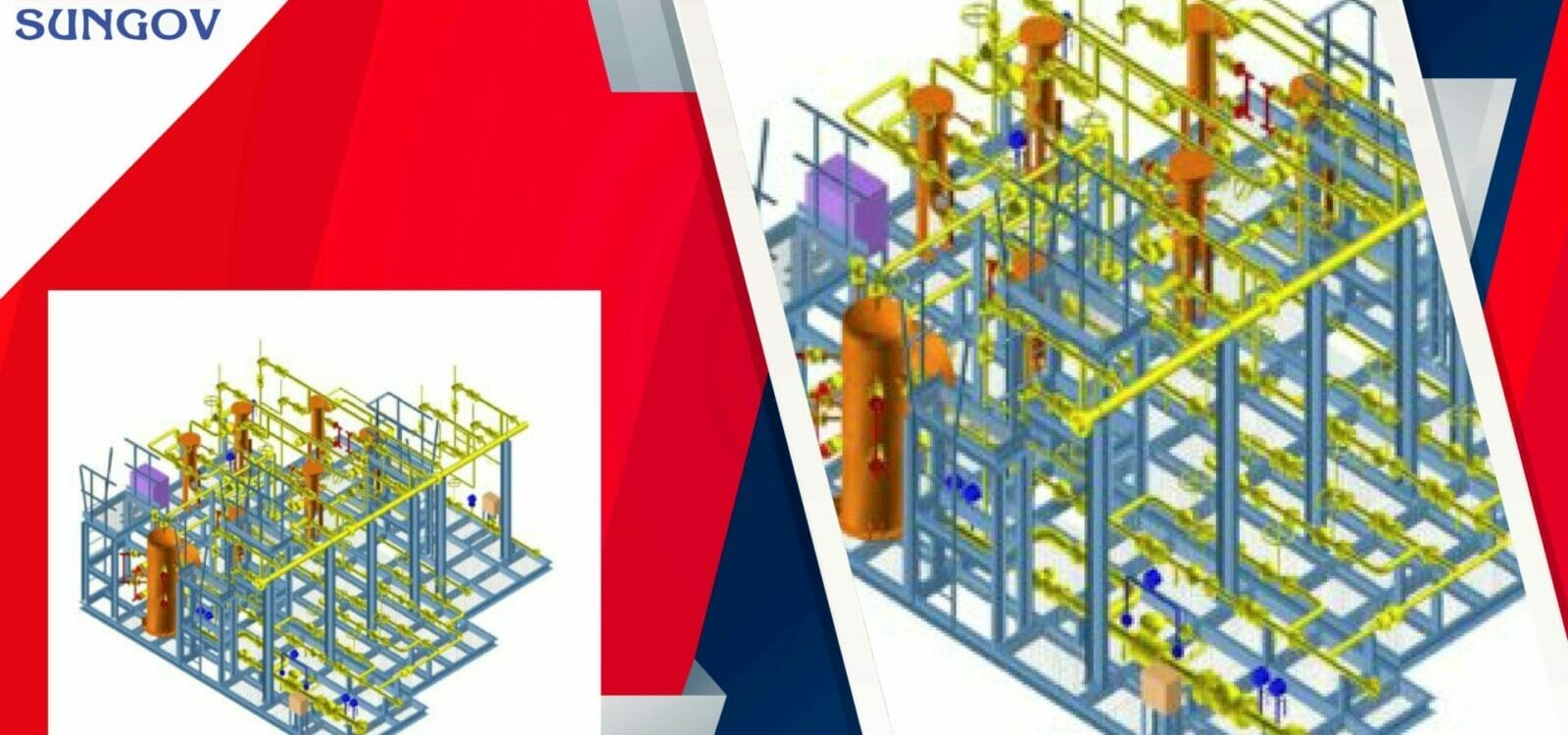

Sungov Engineering is world-class maker of custom-engineered, standard fuel gas conditioning systems that work well for compressors, gas turbines and engine burners. Before natural gas is infused into a gas turbine generator, it is important that they be treated with a fuel gas conditioning system. In a fuel gas conditioning process, natural gas is treated as useable gas. The fuel gas conditioning skid package helps remove even the tiniest of solid/liquid contaminants and alters the gas temperature to the desired condition.

Natural gas must be adequately heated above the gas dew point level to remove condensation inside the system. When the fuel gas treatment package is absent it can lead to irreparable damage to the equipment.

Fuel gas conditioning skid packages from Sungov Engineering help with the following:

- Improves equipment performance

- Reduces maintenance costs

- Limits unprepared repairs

- Extends the lifespan of the equipment

With decades of experience designing, developing and building an efficient fuel gas conditioning system, Sungov Engineering caters to all industrial users of gas as fuel (Petrochemical, Power Plants etc…). Fuel gas conditioning skid packages are optimally engineered and designed for specific requirements. With outstanding quality and performance, you are sure to have the Sungov advantage! Call our experts today to know more!