Fire heaters are used in industrial processes in order to heat gases, fluids and other kinds of materials. There are several types of fired heaters such as radiant heaters, convection heaters, process furnaces, indirect and direct heaters.

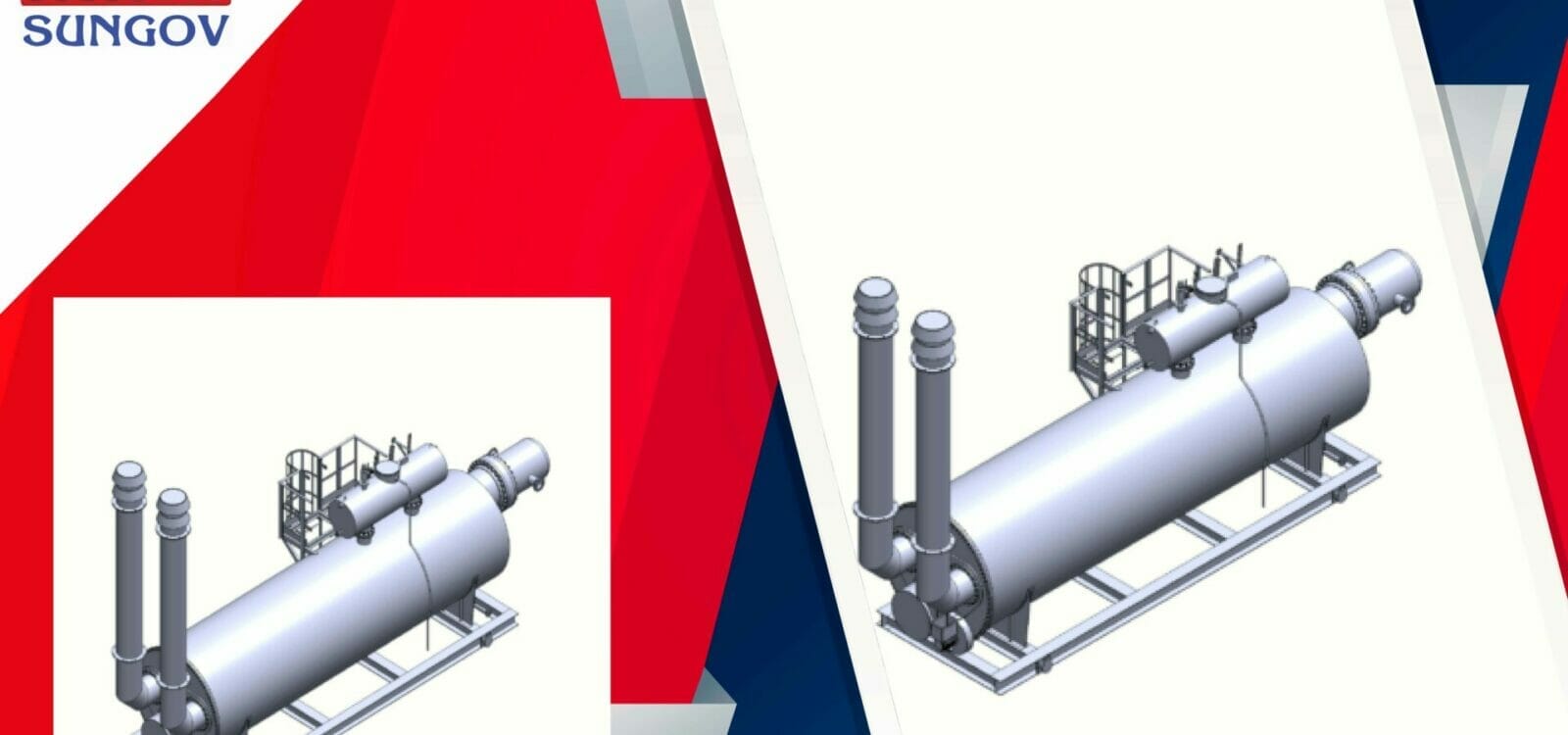

This blog deals specifically with indirect fired line heaters that use a heat transfer fluid to transfer heat. Sungov Engineering manufactures indirect fired line heaters as part of their complete skid mounted packaged system. A variety of industries such as power generation, chemical processing, oil and gas require the services of indirect fired line heaters. These fired heaters are available in customizable sizes and configurations designed specifically for industrial applications.

What Is an Indirect Fired Line Heater?

In industrial applications, an indirect fired line heater (a kind of heat exchanger) is employed specifically to heat fluids and gases without actually coming in contact with the material that requires heating. A heat transfer fluid, mostly glycol, is heated with the help of a combustion source. Natural gas or fuel gas (that which needs heating) is then passed through the heat exchanger and is indirectly heated by the transfer fluid. Since the material that needs heating doesn’t directly come in contact with the source of heat there is minimal risk of contamination and the process is much safer than direct heating methods.

What Are the Advantages Of Indirect Fired Line Heaters In Natural Gas And Fuel Gas Applications?

The indirect fired line heaters or water bath heaters have several benefits and can be used in industries such as chemical processing, power generation and oil and gas. There are several reasons why indirect fired line heaters are preferred over direct heating methods. This blog lists a few of its uses here:

- Versatility: Indirect fired line heaters are employed to heat a variety of fluids, materials and gases and this makes them perfect for a wide number of applications.

- Safety: Since there is no direct contact with the gas stream, there are minimal chances of explosions and fires in this method. This is the safest method employed in the natural gas and fuel gas application.

- Productivity: The indirect fired line heaters are built to achieve high levels of heat transfers. In spite of this, they are adept at a greater efficiency without contaminating the gas stream.

- Low Maintenance: The indirect heaters can go on for long without needing repair or cleaning, making them a cost-effective solution.

- Environmentally Safe: Indirect fire line heaters use heat transfer fluid that can be heated using renewable energy sources such as solar, reducing the dependency on fossil fuels.

Maintenance Of Indirect Fired Line Heaters

Here are a few maintenance tasks that are necessary for the safe and efficient performance of indirect fired line heaters:

- It is necessary to check the heater and its surrounding areas for damages, leaks and other signs of damage

- Clean the heater coils and tubes for any build-up of sediment and scales that can reduce the efficiency of heat transfer

- The control panel and wiring must be checked regularly for any signs of damage

Get in touch with us today to find out more about how we can help you set up the indirect fired line heaters in your process.