Coalescers or Coalescing Filters are innovative separation products that achieve phase separation by coalescence, that is, merging of several small free liquid droplets into a large liquid droplet. Typical applications of Coalescers are:

- Removal of water and liquid hydrocarbons from natural gas or other fuel gases

- Removal of water from diesel or other fuels

- Removal of liquid hydrocarbons (oils) from water

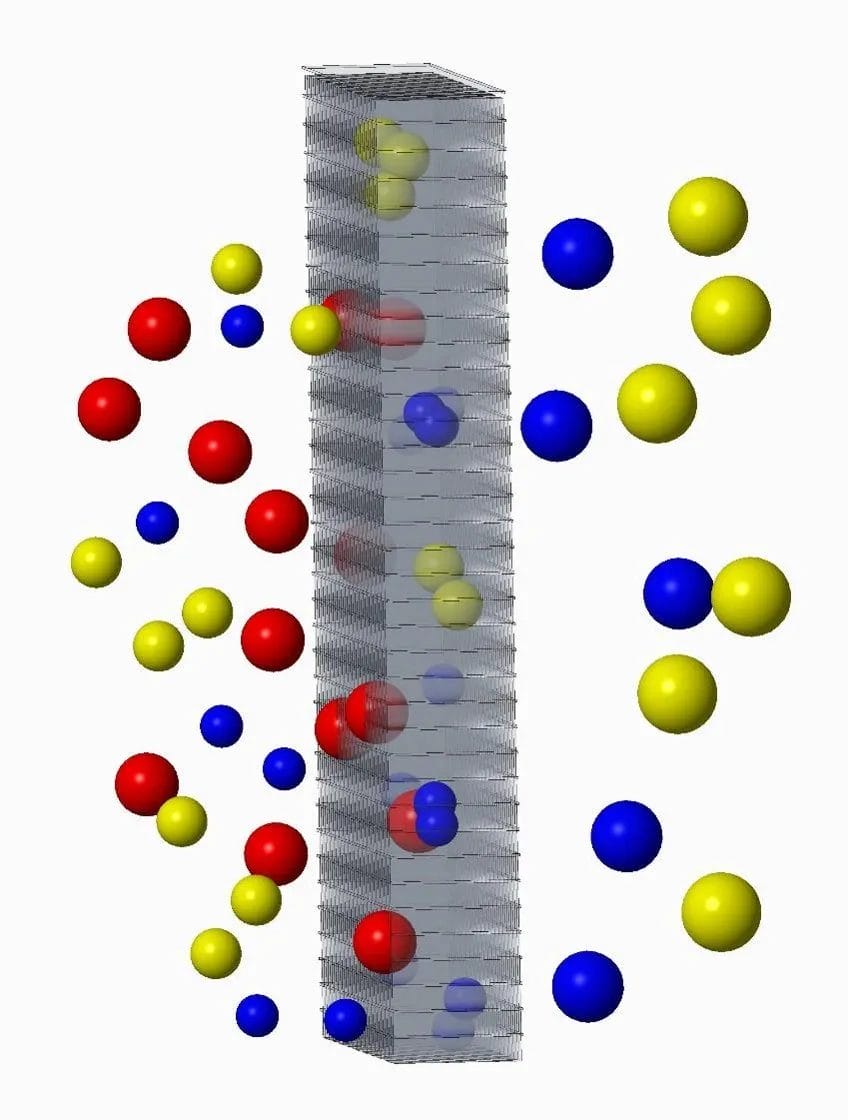

Sungov’s coalescing technology utilizes multi-layered specially structured coalescing filter elements to achieve high separation efficiencies. Sungov manufactures these elements in-house in our clean room facility. Sungov’s high efficiency elements are designed to even separate lube oil aerosols in submicron range that get entrained downstream in gas compressor applications.

Sungov offers Coalescers in both vertical and horizontal configuration depending on various factors like liquid contaminant loading, interfacial tension (IFT) between the liquid contaminant and the service fluid, presence of surfactants (that reduce IFT) in the service fluid and the physical properties of the contaminant/service fluid. Coalescer design is not just a factor of efficient coalescing elements. Sungov places equal importance to vessel sizing in addition to element sizing when designing a coalescer. An undersized coalescer vessel will allow re-entrainment of separated droplets and an oversized coalescer will cost the user an arm and a leg for no reason!

Sungov can offer Coalescer as part of a skid mounted package including necessary pre-filters (Cartridge Filters), piping, instrumentation, valves and automation to provide a hassle-free operation to the end users in oil refinery & terminal, gas processing & distribution and gas based thermal power generation industry.

Contact us today to serve your requirements.