In many industrial processes, fired heaters are one of the top essential components. Used for heating fluids and gases to high temperatures in order to perform specific tasks, these heaters are found in various industries such as oil and gas, chemical, food processing, and more.

In this blog, we will discuss in detail the main features of fired heaters, the different types of fired heaters, and the role of Sungov Engineering in the manufacturing of these heaters.

Main Features of Fired Heaters

Combustion Chamber: This is the area where the fuel is burned to produce heat. Made using refractory materials, this chamber is built to withstand high temperatures.

Heat Exchanger: The heat exchanger is where the fluid or gas to be heated comes in contact with the hot gases produced by the combustion process. This heat transfer process raises the temperature of the fluid or gas.

Fuel Supply: Fired heaters require a continuous supply of fuel to maintain the required temperature. Depending on the type of fired heater, the fuel can be natural gas, propane, diesel, or other fuels.

Control System: A control system is necessary to monitor and maintain the temperature of the fluid or gas to be heated. The control system also ensures that the fuel supply is maintained at the correct rate to avoid overheating or underheating.

What Are the Types of Fired Heaters

Convection Heaters: Convection heaters are used to transfer heat through convection, which is the movement of fluid or gas caused by temperature differences. These heaters are typically used in industrial applications that require heating of liquids, gases, or air.

Radiant Heaters: Radiant heaters transfer heat through radiation. This helps in transferring of heat through electromagnetic waves. These heaters are commonly used in industrial applications where the heating surface needs to be at a higher temperature than the surrounding environment.

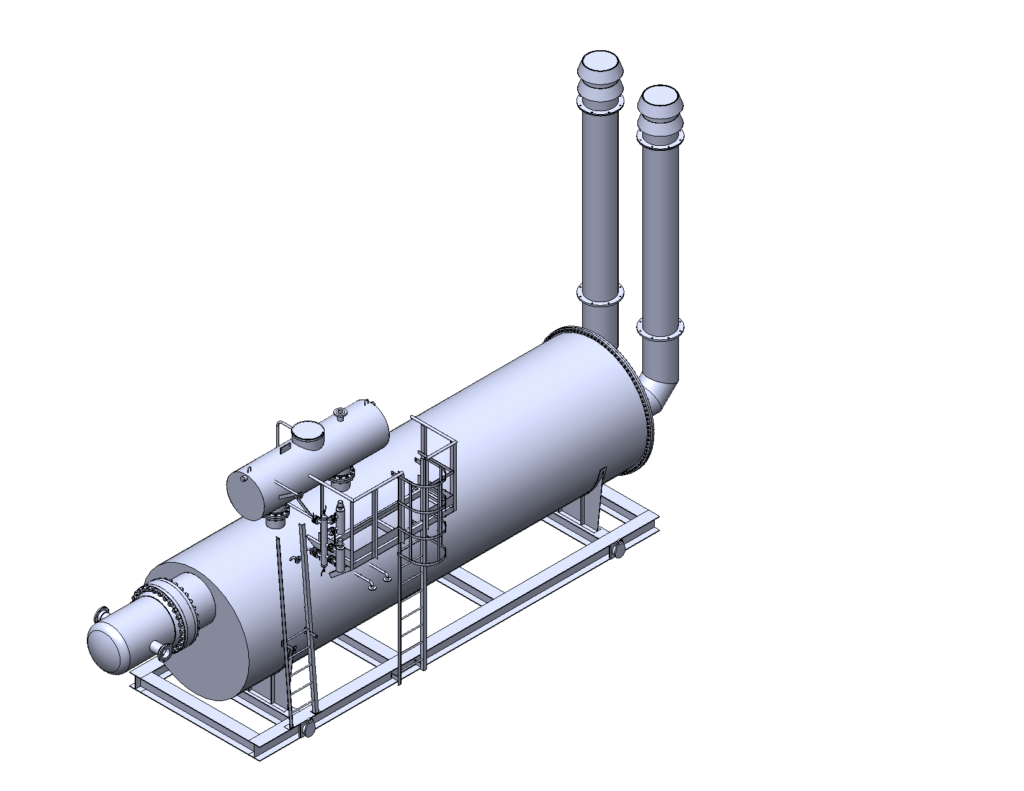

Indirect Fired Line Heater: Indirect fired line heaters are used in oil and gas production facilities to heat the production fluid before it enters the pipeline. These heaters use a heat transfer fluid, such as glycol, to heat the production fluid. Indirect fired line heaters are used to prevent hydrate formation in the pipeline and improve the flow of the production fluid.

Role of Sungov Engineering in the Manufacturing of Fired Heaters

Sungov Engineering is a leading manufacturer of fired heaters. The company offers a wide range of fired heaters that can be customized to meet specific customer requirements. Sungov Engineering has a team of experienced engineers and technicians who design and manufacture fired heaters that are efficient, reliable, and safe.

The company’s fired heaters are designed to meet various industrial standards, such as ASME, API, and ANSI. They are also designed to operate in harsh environments, including offshore oil rigs and arctic conditions.

Sungov Engineering’s fired heaters are used in various industries, including oil and gas, chemical, and food processing.

Conclusion

Heaters are essential components in many industrial processes. They are used to heat fluids and gases to high temperatures to perform specific tasks. The main features of these heaters include a combustion chamber, heat exchanger, fuel supply, and control system. Sungov Engineering is a leading manufacturer of fired heaters, offering a complete range of customized solutions to meet customer requirements. Their expertise in designing and manufacturing fired heaters ensures that customers receive efficient, reliable, and safe products.