In a process plant, whether it is new or when you are expanding or upgrading, have you ever wondered how it is almost always the construction and logistics management that obscures the project and wreaks havoc on the project schedule? If we were to mention a few complications that the traditional stick-build process systems offer. Then those would be: delays and increase in capital costs due to on-site fabrication, long lead times and threadbare detail engineering of interface/terminal points of individual components and lack of proper vendor communication.

This brings us to the topic of the alternative that the current manufacturers have come up with to make the process systems less expensive and highly efficient – Modular Engineered Process Skids.

What is Modular Engineered Process Skid?

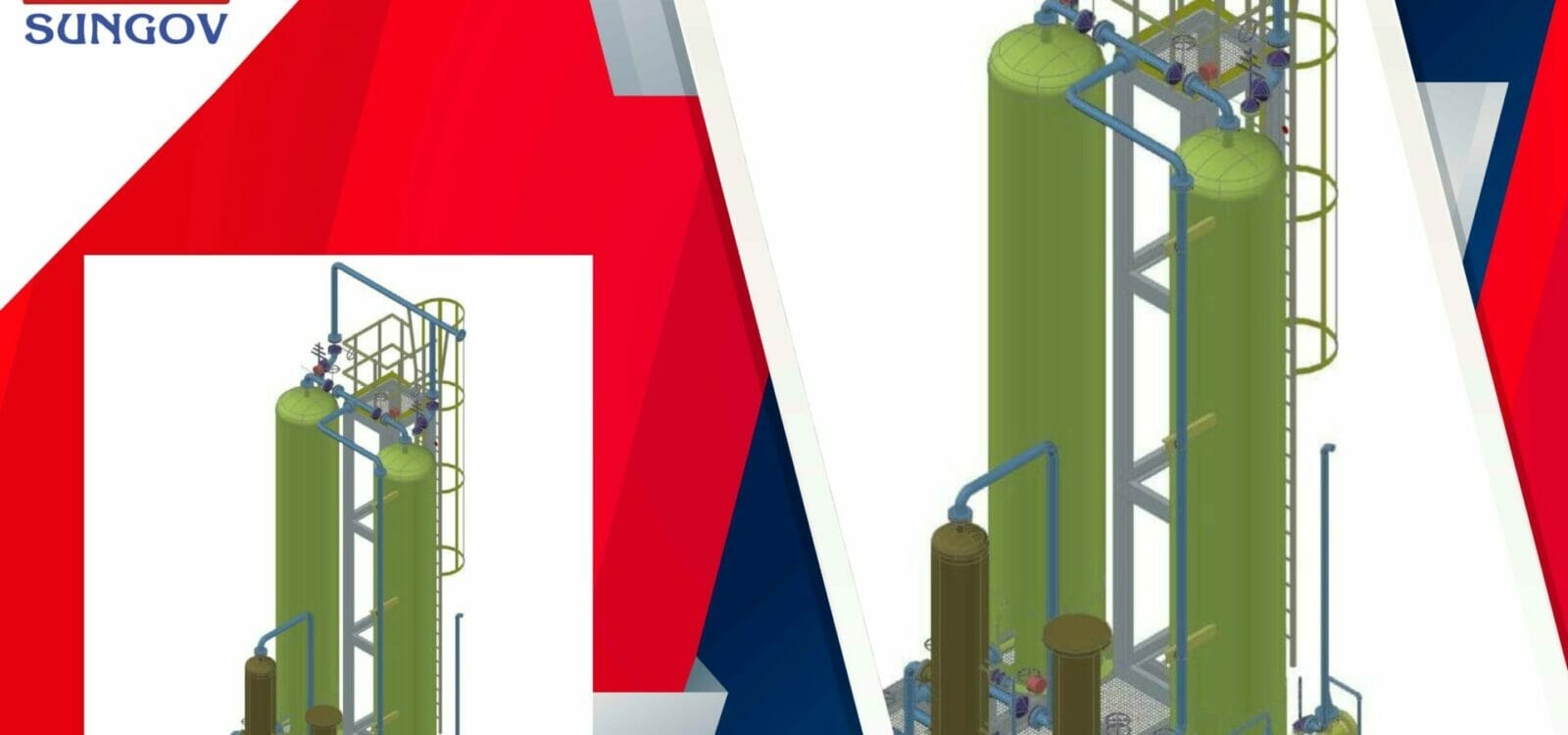

A self-contained process system, Modular Process skid helps in ease of integration and transportation thereby creating shorter project timelines and facilitating an increase in profits. It is basically a mini-process plant that can include the entire process system or individual process applications. It is flexibly designed, engineered and built to serve the industries of petrochemicals/chemicals, oil and gas, power generation, industrial utilities and more to bring their products into the market faster, hassle-free and with greater efficiency.

What are the advantages Sungov Engineering has to offer?

Sungov Engineering has the experience and is well-equipped with engineering and manufacturing competencies. This helps in designing skid-mounted loading systems. We can customize it as per your space and process requirements. The simple plug-and-play solution means that you get the benefit of a shorter project completion cycle and negligible site disruption.

Guaranteed process efficiency along with optimized safety interlocks are added advantages to the meticulously engineered and uncompromised quality skids that we manufacture in-house.

Our wide range of skid-mounted solutions includes:

- Fuel Unloading Skid or Fuel Skids for Tanker Truck Unloading: for unloading of fuels from tankers to storage tanks. A similar system is also offered for feedstock unloading from tankers (for example, ammonia unloading from tanker for a fertilizer plant or a carbon black manufacturing plant) Click here to see our past track record for this application.

- Skid Mounted Pumping System or Fuel/Feedstock Pumping Skid: for transfer of fuel or feedstock from storage tanks to downstream processes

- Fuel Gas Skid Package or Gas Conditioning Skid: for treatment of fuel gas (natural gas, hydrogen gas, biogas) prior to its flow into a gas turbine for combustion. A treated fuel gas has a higher combustion efficiency resulting in direct cost savings for you

- Oil Conditioning Skid Or Fuel Filtration Skid: for treatment of liquid fuels (diesel, fuel oil) prior to their flow into a diesel engine for combustion. A filtered liquid fuel, free of water improves the life of your diesel engine Click here to see our past track record for this application.

We also have the expertise to create custom packages for a variety of applications. Such as Joule Thomson/JT skids, hydrant hose package, water wash skids, deluge skids, heater skids and other filter skids.

With the idea to contain a complete process system, modular process skids that we develop can help you standardize your manufacturing process into reasonable groups. The following features are distinctive of our process skids:

Engineered-to-Order Solutions is designed for the space available at your site and a quick ‘plug into’ your process.

High Quality of Fabrication by our highly trained engineers in controlled environments.

Quicker Delivery means faster market reach. Fabrication and integration of skids in our facility ensure that your onsite work requires minimal site disruption.

Cost Effective as different process systems are built simultaneously. This ensures that you get the same amount of work done at a reduced cost.

Ease of Transport as our Modular skid systems are built compact and robust within frames. Modular process skids can offer your business a matchless mix of flexibility and strength. To know more about how our customized modular process skids work for your process flow, get in touch with our engineers today!