In the oil and gas industry, safety is not just a compliance requirement. It is the very foundation of sustainable operations. One piece of equipment that plays a vital yet often underappreciated role in maintaining gas safety is the flare Knock Out Drum (KOD). This vessel is designed to separate and capture liquids from relief streams before gases are safely flared. While it may seem like just another component in a plant layout, the truth is: the design of a flare knock out drum can make or break safety standards.

Let’s take a deep dive into why its design matters, what factors engineers must account for, and how companies like Sungov Engineering ensure that their KOD solutions align with both efficiency and safety.

The Role of a Flare Knock Out Drum in Gas Safety

When process upsets, maintenance activities, or emergency shutdowns occur, excess gases are directed to the flare system. But these streams are rarely “pure” gases. They often contain entrained liquid droplets and hydrocarbons. Sending these directly to a flare would create multiple hazards:

- Flame instability due to liquid carryover.

- Dangerous emissions from incomplete combustion.

- Mechanical damage to the flare stack caused by slugs of liquid.

- Risk of explosions if liquid hydrocarbons accumulate.

This is where the knock out drum comes in. By separating and holding back these unwanted phases, the KOD ensures that only clean gas reaches the flare tip, maintaining combustion efficiency and preventing catastrophic failures.

Why Design Cannot Be an Afterthought

A poorly designed knock out drum is more than just inefficient—it’s a safety hazard waiting to happen. The consequences include excessive pressure drop, liquid carryover, undersized capacity, or even drum failure under surge conditions.

There are design considerations that will influence how well the drum will protect downstream systems during real-world operations. The design process must carefully address:

- Capacity requirements to handle peak gas flows.

- Residence time to ensure effective liquid-gas separation.

- Mechanical integrity for high-pressure and high-temperature conditions.

- Ease of maintenance for long-term reliability.

Key Factors in Flare Knock Out Drum Design

Designing a flare KOD isn’t a one-size-fits-all task. Each facility has unique process requirements, and the vessel must be engineered accordingly. Here are the critical factors that go into the design:

1. Sizing and Capacity

Getting the size wrong is a common pitfall. A smaller drum may fail to handle surge conditions, while an oversized drum is unnecessarily costly. Engineers must consider:

- Maximum gas and liquid flow rates.

- Surge scenarios during emergency depressurization.

- Operating pressure and temperature ranges.

2. Separation Efficiency

The effectiveness of a knock out drum depends on its ability to separate liquid droplets. Design elements include:

- Adequate liquid holdup time.

- Use of demisters or vane packs for fine separation.

- Proper inlet and outlet nozzle placement to minimize re-entrainment.

3. Mechanical Design and Safety Margins

Flare systems operate under high pressure and often handle corrosive fluids. The vessel must be designed for:

- Correct thickness and material selection.

- Adherence to international design codes like ASME Section VIII.

- Built-in safety margins for unexpected surges.

4. Orientation: Vertical vs. Horizontal Drums

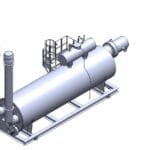

Depending on process requirements, the drum may be designed vertically or horizontally:

Vertical KODs – Compact footprint, better for limited space, efficient for low liquid load.

Horizontal KODs – Preferred for large gas flows with higher liquid content, easier liquid handling.

5. Liquid Handling and Draining

Captured liquids must be safely removed without disrupting gas flow. Design considerations include:

- Adequate liquid outlet piping.

- Provision for pumps or gravity draining.

- Level control systems to prevent liquid buildup.

Common Design Mistakes and Their Risks

It’s equally important to know what not to do when designing a flare knock out drum. Common mistakes include:

- Ignoring worst-case scenarios like total plant depressurization.

- Improper nozzle placement, leading to liquid re-entrainment.

- Underestimating droplet size distribution, which reduces separation efficiency.

- Poor liquid level control, resulting in overflow into the flare header.

The risks of these mistakes range from frequent shutdowns and flare damage to major safety incidents. In short, cutting corners in design is never an option.

Compliance with Standards and Regulations

Knock out drums are not only an engineering requirement but also a regulatory one. Global standards mandate their inclusion in flare systems:

- API 521 provides guidelines on flare system design and relief handling.

- ASME codes define mechanical design standards for pressure vessels.

- Environmental norms demand clean combustion at flare tips, which is only possible when liquids are removed.

The Sungov Engineering Advantage

At Sungov Engineering, the approach to flare knock out drum design goes beyond standard calculations. Each solution is:

- Custom-engineered to match client-specific process conditions.

- Manufactured with precision, ensuring compliance with ASME, API, and other international codes.

- Optimized for safety and efficiency, balancing capital costs with long-term reliability.

- Tested rigorously, ensuring zero compromise on quality.

By combining engineering expertise with advanced manufacturing capabilities, Sungov ensures that every flare knock out drum serves its true purpose—safeguarding lives, equipment, and the environment.

Looking Ahead: The Future of Flare Knock Out Drum Design

As industries push toward greater efficiency and sustainability, flare system design—including KODs—is also evolving. Trends to watch include:

- Integration with digital monitoring systems for real-time level and pressure control.

- Advanced separation internals for higher efficiency in compact designs.

- Use of corrosion-resistant alloys to extend equipment lifespan in harsh environments.

- Smarter liquid handling systems for safer disposal and recovery.

When it comes to designing such critical equipment, experience and precision matter. And this is where Sungov Engineering stands out—delivering robust, reliable, and custom-designed knock out drums that keep operations safe and efficient.

In gas safety, details matter—and the design of your flare knock out drum is one detail you cannot afford to overlook.

FAQs on Flare Knock Out Drum Design and Gas Safety

A fuel gas scrubber removes liquids, oil mist, and particles from gas streams, ensuring clean fuel gas and preventing equipment damage.

A natural gas scrubber cleans gas for fuel use, while a knock out drum separates liquids before gases reach the flare, protecting against flare damage and safety risks.

A trusted knock out drum manufacturer ensures compliance with ASME and API standards, delivers custom sizing, and guarantees safe, efficient gas handling.

Key factors include proper sizing, residence time, demisters or vane packs, correct orientation, and efficient liquid draining for maximum separation and gas safety.