The Importance of a Knock-Out Drum

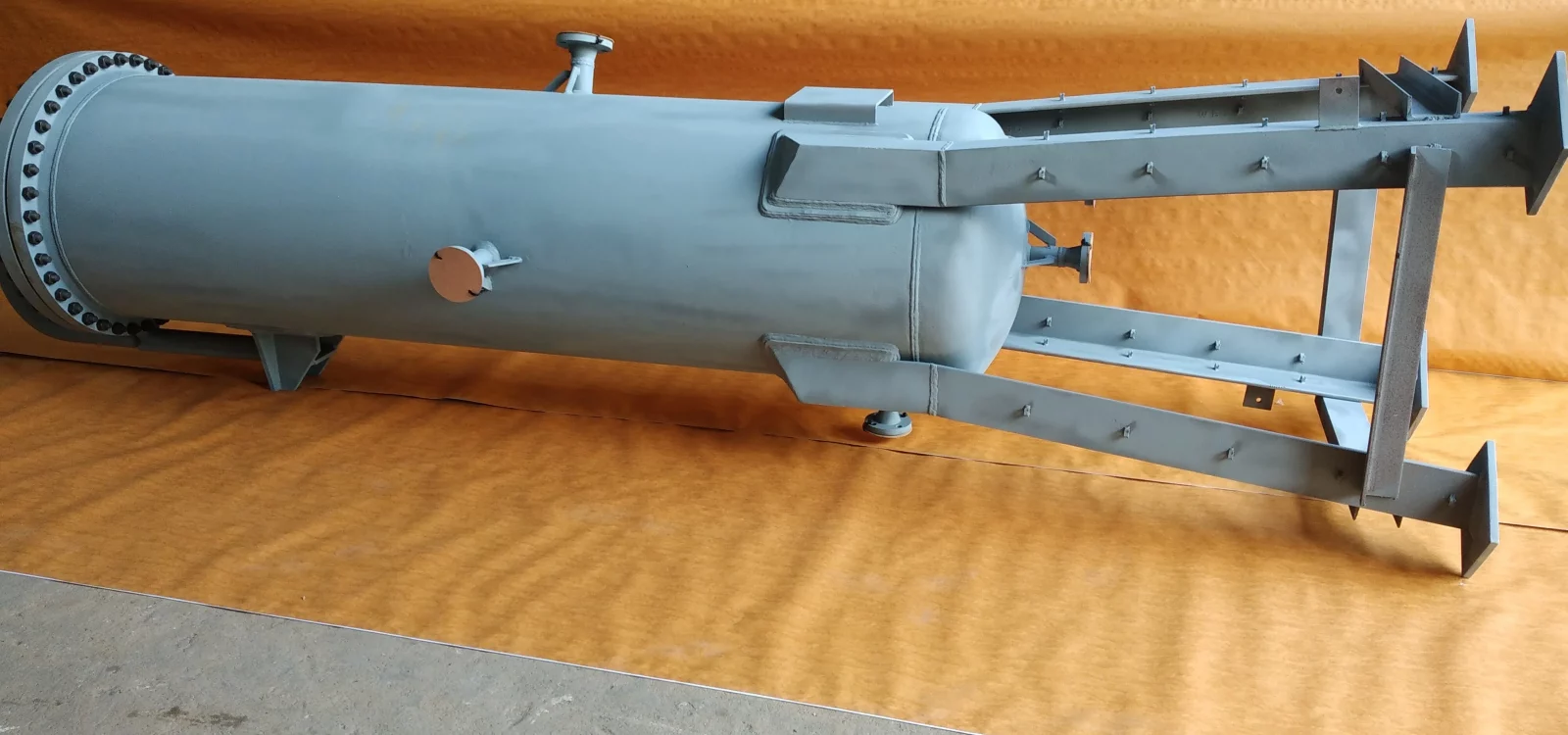

The vessel in a refinery that is intended to separate and collect the condensed liquid from process gases and to remove it is called a knockout drum. Called by other names such as mist eliminators, scrubber separators, vane pack separators, demister pad separators, inertial separators, the knock-out drum functions as one of the main components in a refinery and is made available in horizontal and vertical configurations.

What are the Functions of a Knock-Out Drum

The knock-out drum’s applications are listed as follows:

- Removal of oil or water from fuel gases, flare gas, other process gases

- Elimination of water or oil that enters the compressor during the point of suction

What You Need to Know About Horizontal Configuration

The design of a knock-out drum is generally decided based on the space available and the operating parameters. A horizontal drum is used when the flow rate is high and there is a need for enormous liquid storage capacity. Some of the advantages of having a horizontal knock-out drum are:

- Can handle larger liquid loads

- Has low pressure drop

The design of the knockout drum is determined by the path in which the vapor enters and exits the drum. Some of the popular horizontal configurations are as below:

- Vapor enters the center and exits at each end on the horizontal axis

- Vapor enters one end of the vessel exits the top of the opposite end (internal baffling-none)

- Vapor enters each end on the horizontal axis and exits the central outlet

What You Need to Know About Vertical Configuration

When the load of the liquid is low and when there is a considerable space crunch, the vertical knock-out drum configuration is a preferred choice. The vertical knock-out drum designs are as below:

- Vapor enters the vessel radially and exits at the top of the vessel’s vertical axis. However, note that the inlet stream has to be baffled and the flow directed downwards

- Vapor flow enters tangentially from the tangential nozzle, and gravity plays its part in determining the settlement of the liquid at the bottom, while the vapor exits from the outlet at the top of the drum’s vertical axis

What is Common Between the Knock-out Drums

The knock-out drums include the liquid zone, vapor area, inlet and outlet lines, liquid level indicator, control valve and a de-entrainment pad.

Sungov Advantage for Vessel Fabrication Using Knockout Drums

With over three decades of experience, we at Sungov Engineering are always brimming with ideas and experience to assist you in your project involving vessel fabrication. Sungov Engineering manufactures knockout drums for several applications including natural gas, flare gas, and other fuel gas. The drums are generally constructed to ASME Sec VIII Div. 1 Code of construction with/without ASME stamping.

Our team of experts who are always passionate about what they do will gladly discuss your process and assist you with your questions. Call us today!