When you are looking at the oil and gas industry, you will understand that efficiency and safety are not goals but lifelines. When you are working with high-pressure gas, variable weather, and volatile substances, the margin for error shrinks dramatically. There should be practically none. That’s where indirect fired water bath heaters step in. This offers a safe, consistent, and highly efficient heating solution for process fluids and natural gas.

At Sungov Engineering, we’ve seen firsthand how the right heating solution can transform operational reliability. This blog dives into how industrial indirect fired water bath heaters work, why they’re trusted across upstream, midstream, and downstream sectors, and what makes them a smart investment for long-term safety and performance.

What Is an Indirect Fired Water Bath Heater?

Before diving into the benefits, let’s get the basics right.

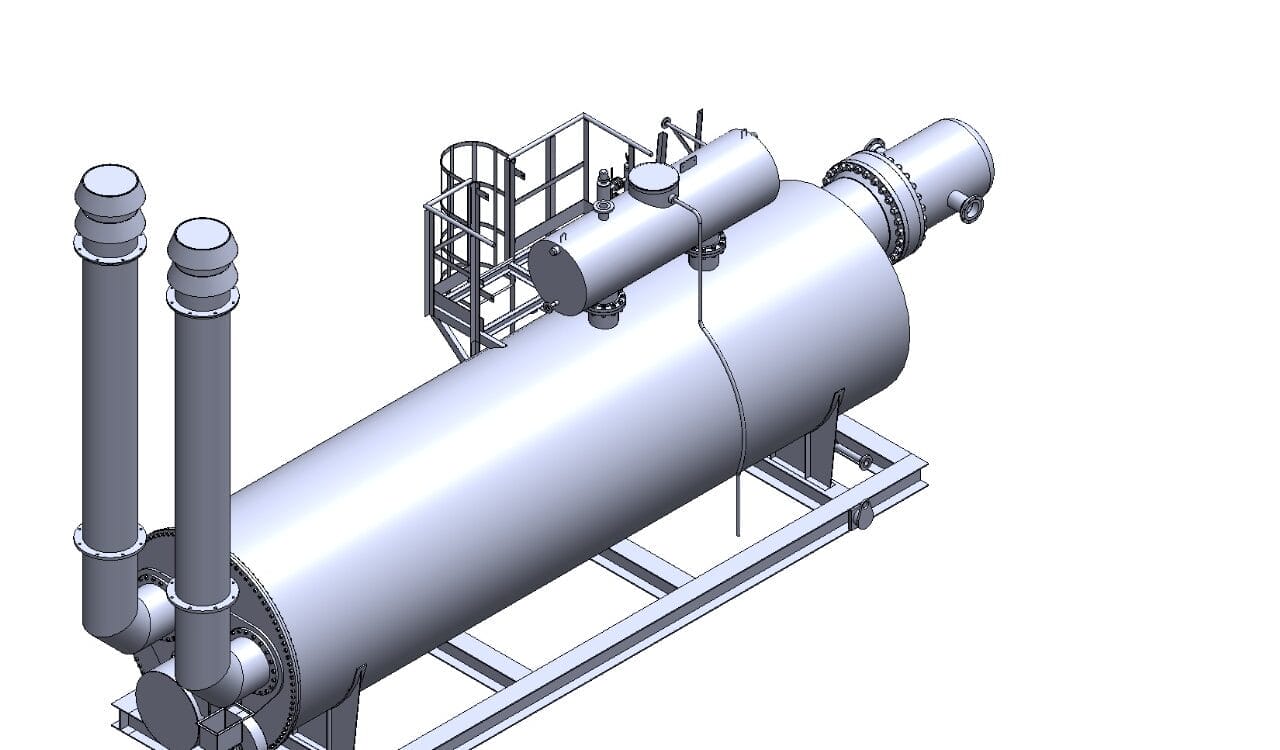

An indirect fired water bath heater is a type of heater used to raise the temperature of natural gas or process fluids without exposing them directly to flame. It’s a three-part system:

Fire Tube – This is where combustion occurs

Water-Glycol Bath – a heat transfer medium that surrounds the fire tube

Process Coil – The place where the actual fluid or gas that has to be heated flows

Instead of heating the process fluid directly, the fire heats the water bath, which in turn heats the coil. This layered approach provides gentle, even heating, minimizing thermal stress and risk.

Why Safety Comes First in Oil & Gas

Safety is a non-negotiable in oil and gas environments. High pressures, flammable gases, and remote locations all present unique challenges. One of the reasons indirect gas-fired process heaters are so popular is their inherently safe design.

Because there’s no direct flame contact with the process fluid, there’s far less risk of ignition or thermal degradation. The water bath acts as a buffer, absorbing rapid temperature changes and preventing overheating. In environments where safety protocols must be airtight, indirect heating makes a lot of sense.

And at Sungov, safety isn’t an afterthought—it’s engineered into every unit we manufacture. Our heaters come with flame arrestors, high-temperature shutdown systems, pressure relief valves, and full instrumentation to ensure safe operation 24/7.

Efficiency You Can Count On

Let’s talk about something every operations manager loves: reliability and fuel efficiency.

Indirect fired heaters for oil and gas operations are known for their steady and even heating. No hot spots. No cold spots. No sudden surges. That consistency means smoother operations and better control of fluid properties—especially important when dealing with varying gas compositions or cold ambient temperatures.

Let us look at how indirect fired water bath heaters can boost efficiency:

1. Uniform Temperature Control: Reduces risk of cracking or condensate formation in gas pipelines

2. Fuel Flexibility: Most designs can work with natural gas, diesel, or propane

3. Low Maintenance: Fewer moving parts and stable thermal cycles mean lower operating costs over time

And when we say low maintenance, we mean it. Sungov’s water bath heaters are designed with robust metallurgy, corrosion-resistant coils, and easy-access panels that keep downtime to a minimum.

Applications That Make an Impact

Let us understand where these heaters fit in oil & gas operations.

1. Gas Pressure Reduction Stations

After gas is depressurized at letdown stations, it can get extremely cold—sometimes below freezing. Indirect fired heaters warm the gas before and after pressure reduction, preventing hydrate formation.

2. Pipeline Preheating

In cold regions, preheating ensures smooth flow and prevents gas from liquefying or slowing down due to temperature drops.

3. Separator Inlet Heating

Heating before gas-liquid separation improves the separation efficiency and prevents downstream freezing.

4. Dehydration Units

Keeping the gas warm improves the performance of glycol dehydrators.

Built to Withstand Harsh Conditions

What sets a good heater apart from a great one? Durability. When equipment sits in harsh weather—sandstorms, salt spray, or monsoon moisture—it has to be tough.

At Sungov Engineering, we manufacture all our indirect fired heaters for oil and gas with:

1. ASME-certified pressure vessels

2. Corrosion-resistant coatings and linings

3. Insulated enclosures to improve energy efficiency and protect operators

4. Custom skids for easy transport and field installation

We also offer custom engineering to fit space constraints, unusual elevation conditions, or extreme weather environments.

Easy Integration with Plant Control Systems

Our clients often ask, “Can we integrate these heaters with our SCADA or DCS?” The answer is: absolutely.

Our systems are designed with instrumentation panels that can be seamlessly connected to your plant’s control room. This means real-time monitoring of:

1. Bath temperature

2. Gas outlet temperature

3. Burner status`

4. Emergency shutdowns

5. Pressure and flow control

The result? Greater operational visibility and faster decision-making.

What Makes Sungov Stand Out?

There are plenty of heater manufacturers in the market. So why choose us?

1. Engineering Depth: Every unit we build is backed by decades of process engineering experience in high-pressure gas environment

2. Customization: Need dual-fuel burners? A compact footprint? Remote ignition? We’ll design around your needs.

3. After-Sales Support: From commissioning assistance to spare parts and annual maintenance contracts—we’re with you for the long haul.

Most importantly, we treat your uptime like our business depends on it—because it does.

Indirect gas-fired process heaters are not just a safer alternative—they’re a smarter one. Whether you’re in production, transmission, or refining, heating plays a critical role. And choosing a solution that balances safety, efficiency, and durability can make all the difference.

At Sungov Engineering, our goal is simple—to help you operate smarter, safer, and more reliably. If you’re considering adding or upgrading a heater in your facility, let’s talk. Our team will work closely with you to design a system that fits your application, budget, and long-term operational goals.

Get in touch with Sungov Engineering today to learn more about our industrial indirect fired water bath heaters for oil & gas.

Frequently Asked Questions

Ans: Indirect fired heaters for oil and gas use a heat‑transfer medium (commonly a water‑glycol bath) to gently warm natural gas or process streams without direct flame contact. This design prevents hot or cold spots, reduces ignition risk, and ensures uniform temperature control.

Ans: Indirect gas‑fired process heaters isolate the flame from the fluid stream via a water bath. This layered approach eliminates flame‑to‑gas contact, reduces thermal stress, prevents ignition risks, and includes safety interlocks like flame arrestors and emergency shutdown systems.

Ans: Industrial indirect fired water bath heaters offer steady, even heating and prevent hydrate formation at pressure reduction stations or pipeline inlets. They support fuel flexibility (gas, diesel, propane), have low maintenance, and deliver consistent temperature control—critical for efficient and trouble‑free gas flow.

Ans: These heaters are installed at gas pressure reduction stations, pipeline pre‑heating applications, separator inlet heating, and gas dehydration units. They enhance separation efficiency, prevent freezing, and improve downstream process reliability.