Fuel unloading skids with metering are integrated systems that are designed to safely transfer fuel from tankers or containers. All this while accurately measuring the quantity delivered. These systems play a critical role wherever fuel custody transfer, cost control, and operational transparency are essential.

In industries where fuel is both a high-value commodity and a critical input, even the smallest inaccuracies can translate into significant financial losses or disputes. Especially in industries such as oil and gas, power generation, and heavy manufacturing. That is why metered fuel transfer skids are no longer optional add-ons but a core operational requirement.

What Is a Fuel Unloading Skid With Metering?

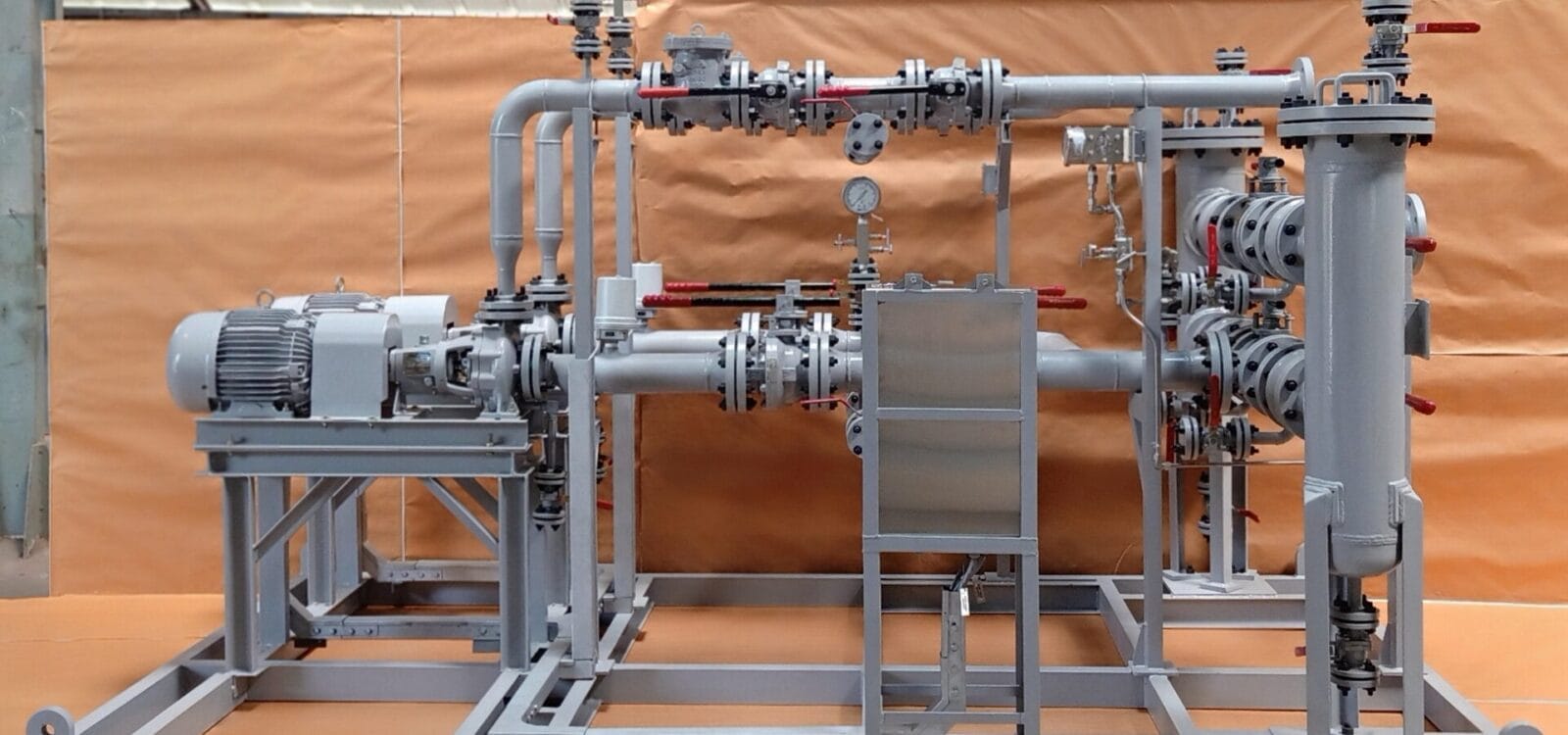

A fuel unloading skid with metering is a skid-mounted package that typically includes the following:

- Pumps

- Flow meters

- Filters or strainers

- Control valves

- Instrumentation and safety components

Together, these components enable controlled fuel unloading and precise volume measurement during transfer from road tankers, railcars, or storage containers to bulk tanks or process systems. This ensures accountability and operational efficiency.

Why Accuracy in Fuel Unloading Is Critical

Fuel handling is not just a mechanical process. It is a financial and regulatory one. Inaccurate measurements can impact the following:

- Billing and invoicing

- Inventory reconciliation

- Regulatory compliance

- Operational planning

Even a small percentage error during repeated transfers can accumulate into substantial loss over time. When there are metered fuel transfer skids, they can address this risk by providing real-time, verifiable measurement at the point of unloading.

1. Custody Transfer and Commercial Accountability

One of the most important reasons that accuracy matters is custody transfer. When fuel ownership changes between suppliers, transporters, and end users, the measured quantity becomes the basis for payment, contracts and dispute resolution.

Fuel unloading skids with metering can ensure:

- Transparent volume measurement

- Reduced manual errors

- Documented transfer data

In high-volume fuel operations, this level of accuracy can protect both buyers and sellers.

2. Inventory Control and Loss Prevention

Without accurate metering, operators often rely on:

- Tank level calculations

- Manual dip readings

- Estimated volumes

These methods are prone to errors caused by:

- Temperature variations

- Human oversight

- Calibration inconsistencies

Metered fuel transfer skids provide direct volumetric measurement. This makes inventory tracking more reliable and reduces unaccounted fuel losses.

This is especially critical in facilities handling diesel, furnace oil, or aviation fuels, where margins are tight and compliance requirements are strict.

3. Regulatory and Audit Compliance

Fuel handling operations are often subject to:

- Weights and measures regulations

- Environmental audits

- Internal and external financial audits

Accurate metering helps facilities:

- Maintain traceable fuel transfer records

- Demonstrate compliance during inspections

- Avoid penalties due to discrepancies

Fuel unloading skids with metering support automated data logging, making audits smoother and less disruptive.

4. Operational Efficiency and Time Savings

Accuracy is not only about numbers, it also affects operational speed and reliability. Metered fuel transfer skids:

- Reduce unloading time through controlled flow rates

- Eliminate repeated verification steps

- Minimize rework caused by measurement disputes

This is particularly valuable at terminals and industrial plants where multiple tankers are unloaded daily.

5. Safety and Process Stability

Uncontrolled or poorly monitored fuel unloading increases the risk of:

- Overfilling tanks

- Spills and leaks

- Pump cavitation

Metered fuel transfer skids integrate flow control and safety instrumentation, ensuring:

- Stable unloading rates

- Automatic shutoff at preset volumes

- Safer handling of flammable fuels

Accurate measurement directly supports safer operations.

6. Applications Across Industries

Fuel unloading skids with metering are used in a wide range of sectors, including:

- Oil & Gas Terminals: For diesel, condensate, and fuel oil unloading

- Power Plants: Accurate fuel supply to generators and turbines

- Refineries and Petrochemical Plants: Controlled transfer of feed and utility fuels

- Mining and Heavy Industry: Bulk fuel handling for equipment fleets

Across all these applications, accuracy ensures continuity and cost control.

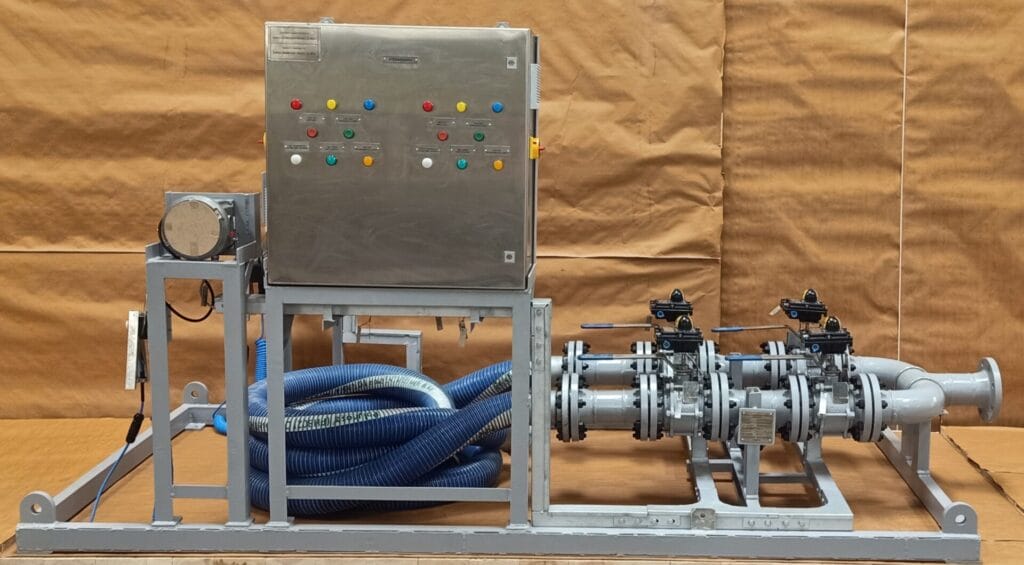

7. Why Skid-Mounted Systems Are Preferred

Skid-mounted metered fuel transfer skids offer several practical advantages:

- Factory-assembled and tested

- Faster installation on site

- Compact and modular design

- Easy relocation or expansion

For facilities operating in remote or space-constrained locations, skid-mounted systems simplify project execution while maintaining measurement integrity.

8. Key Components That Ensure Accuracy

The performance of fuel unloading skids with metering depends on component quality and system integration.

Critical elements include:

- Flow Meters: Positive displacement, turbine, or Coriolis meters selected based on fuel type

- Filtration: Prevents debris from affecting meter accuracy

- Instrumentation: Pressure and temperature compensation where required

- Calibration Systems: Maintain long-term measurement reliability

Choosing the right configuration is essential to achieving consistent accuracy over the system’s lifecycle.

Common Questions About Fuel Unloading Skids With Metering

Why are fuel unloading skids with metering important?

They ensure accurate measurement of fuel during unloading, preventing financial losses, disputes, and compliance issues.

What fuels can be handled using metered fuel transfer skids?

They are commonly used for diesel, furnace oil, aviation fuel, kerosene, and other liquid fuels.

Are metered fuel transfer skids suitable for high-volume operations?

Yes. They are specifically designed to handle repeated, high-volume transfers with consistent accuracy and reliability.

The Cost of Inaccuracy: A Real-World Perspective

In large fuel operations, even a 1–2% measurement error can lead to:

- Significant annual revenue loss

- Inventory mismatches

- Supplier disputes

Investing in fuel unloading skids with metering is not just a technical decision but a financial safeguard.

Accuracy in fuel handling is no longer a luxury but a necessity. Fuel unloading skids with metering provide the precision, transparency, and control required in modern fuel transfer operations.

By integrating reliable measurements with safe unloading practices, metered fuel transfer skids help organizations:

- Protect revenue

- Improve operational efficiency

- Meeting regulatory expectations

In environments where every liter counts, accuracy is not just important, it is everything.

Frequently Asked Questions

Fuel unloading skids with metering are skid-mounted systems used to safely unload fuel from tankers or containers while accurately measuring the exact volume transferred. They combine pumps, flow meters, filtration, and control instrumentation to ensure precise, accountable fuel transfer.

Accuracy is critical because fuel is a high-value commodity. Even small measurement errors can lead to financial losses, inventory mismatches, billing disputes, and compliance issues. Metered fuel transfer skids provide real-time, verifiable measurement at the point of unloading, ensuring transparency and cost control.

Fuel unloading skids with metering are commonly used in oil & gas terminals, power plants, refineries, petrochemical facilities, mining operations, and heavy manufacturing. Any industry handling large volumes of liquid fuel benefits from accurate measurement and controlled unloading.

Metered fuel transfer skids are designed to handle a wide range of liquid fuels, including diesel, furnace oil, kerosene, aviation fuel, and other petroleum products. The skid configuration and flow meter type are selected based on fuel properties and operating conditions.

Yes. Fuel unloading skids with metering are widely used for custody transfer because they provide accurate, documented volume measurement. This data forms the basis for commercial transactions, invoicing, and dispute resolution between suppliers, transporters, and end users.