When it comes to ensuring safe, consistent, and reliable heating for natural gas and industrial fluid streams, industrial indirect fired water bath heaters continue to be one of the most trusted technologies. This may not be the flashiest equipment on a plant site, but their importance in process heating, gas preheating, and pressure reduction systems is undeniable. For companies that are looking for a dependable heating solution that performs even in harsh conditions, these heaters offer a balance of efficiency, stability, and operational simplicity.

In this blog, we will look closely at how these systems work, why industries depend on them, and how companies like Sungov Engineering can design and engineer tailored solutions for complex operations.

What Exactly Is an Indirect Fired Water Bath Heater?

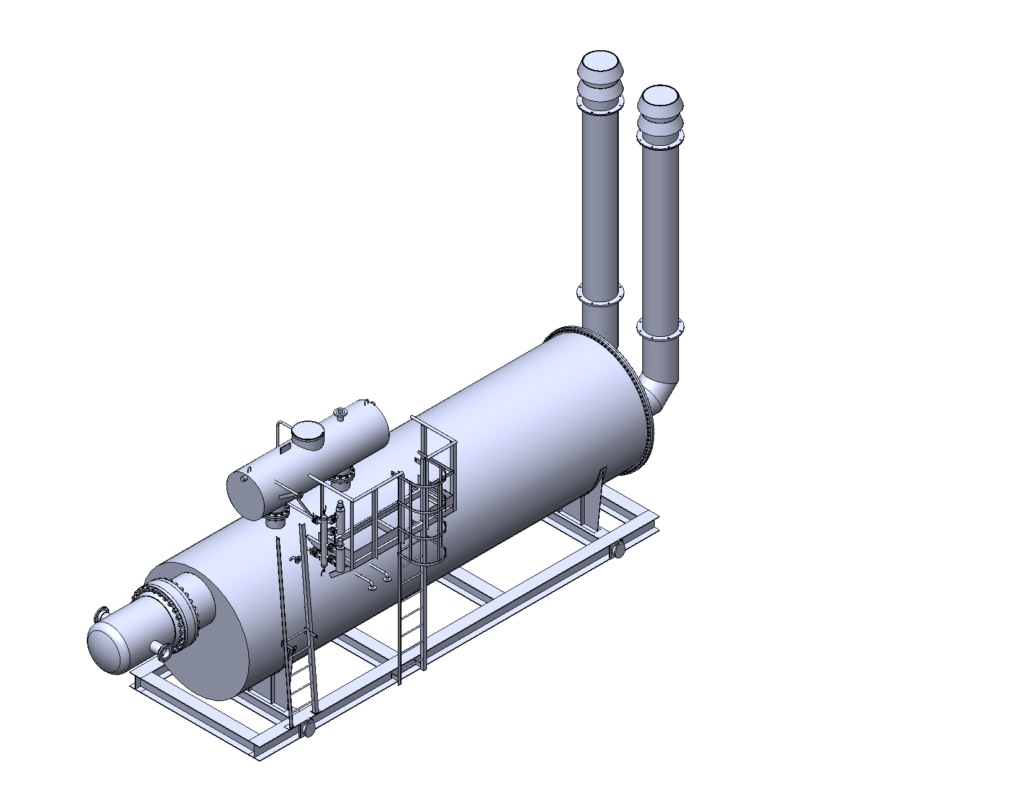

At its core, an industrial indirect fired water bath heater is a heating system where the heat is transferred indirectly to the process fluids. Instead of exposing the gas or liquid directly to the flame, the burner heats a fire-tube that is submerged inside a bath filled with water and glycol.

This water bath acts like a thermal buffer. This means that it absorbs the heat from the flame and transfers it gradually to the process coil. When using this approach you can be sure of preventing thermal shock, ensure steady temperature control, and avoid overheating sensitive process fluids.

These heaters are extensively used where gas needs to be heated before pressure reduction, to prevent freezing or hydrate formation. They also find applications in upstream, midstream, and downstream oil and gas operations, petrochemical plants, and power generation facilities.

How an Indirect Gas-Fired Process Heater Works

To understand the value these systems bring, it helps to look at their components and working principle:

1. Fire-tube and Burner

The burner ignites fuel—typically natural gas or diesel—to heat the fire-tube. Because the flame never touches the process stream directly, it remains a safer option compared to direct-fired units.

2. Water-Glycol Bath

The bath solution absorbs heat from the fire-tube and maintains uniform temperature distribution. This bath ensures that even if the burner output fluctuates, the process fluid experiences steady heating.

3. Process Coil

The gas or liquid flows through a coil immersed in the heated bath. Heat transfer is gentle yet efficient, making the system ideal for fluids that are sensitive to sudden temperature changes.

4. Expansion Tank, Controls, and Safety Systems

Automatic temperature controllers, flame arrestors, pressure relief valves, and level indicators work together to maintain safe operation. Many modern units include PLC-based monitoring for enhanced reliability.

Why Industries Prefer Indirect Fired Systems

Industrial heating equipment must balance performance, safety, and durability—qualities that indirect fired heaters offer naturally. Let’s look at why they remain a popular choice:

1. No Direct Flame Contact

Since the flame interacts only with the water bath and not the process stream, the risk of overheating, cracking, or ignition inside the pipeline is eliminated. This makes them especially suitable for volatile gases.

2. Excellent Temperature Control

The thermal inertia of the water-glycol bath helps maintain steady outlet temperatures. Plants where even small temperature deviations cause operational issues benefit from this consistency.

3. Protection Against Hydrate Formation

In gas pressure-reduction systems, rapid expansion can lower temperature enough to form hydrates. Preheating ensures uninterrupted gas flow and protects metering and regulating stations.

4. Versatility and Application Range

Whether it’s heating natural gas, maintaining waxy crude at flowable temperatures, or supporting chemical processes, these heaters adapt well across multiple industries.

5. Long Service Life

With proper engineering and maintenance, water bath heaters offer long operational life. Their design simplicity reduces frequent component failures and ensures smooth long-term functioning.

Applications: Where You’ll Find These Heaters in Action

Different industrial setups rely on water bath heaters for different reasons. Some of the most common applications include:

- City gas distribution (CGD) networks for preheating natural gas before pressure reduction.

- Upstream oil and gas fields where flow assurance is critical, especially when gas is rich in moisture.

- Compressor stations and metering stations to maintain optimum gas temperature for accurate metering.

- Pipeline installations where sudden cooling might damage equipment.

- Chemical and petrochemical plants that require steady process fluid heating.

Design Considerations: What Makes a Good Water Bath Heater?

Not all heaters are built the same. A well-designed unit considers efficiency, safety, and the realities of day-to-day industrial operation. When Sungov Engineering develops heating systems, some of the key considerations we include are:

1. Optimized Fire-Tube Geometry

The fire-tube design impacts heat absorption and distribution. Proper sizing ensures efficient fuel usage and prevents hotspots.

2. Coil Material and Configuration

Depending on the process fluid and temperature requirement, coil material selection—often carbon steel or stainless steel. This plays an important role in corrosion resistance and longevity.

3. Bath Fluid Selection

A water-glycol mixture is used in most climates, while extremely cold regions demand specific anti-freeze blends to avoid bath solidification.

4. Accurate Temperature Controls

Thermostats, temperature switches, and burners must work together seamlessly. Automated control systems reduce human involvement and enhance safety.

5. Safety Accessories

From flame sensors to pressure relief valves and emergency shutdown valves (ESDVs), each component must be designed with careful attention to reliability.

Advantages of Choosing Sungov Engineering’s Water Bath Heaters

Sungov Engineering has built a reputation for delivering high-performance filtration and process equipment across industries. We understand fluid dynamics, thermal behavior, and industrial operating conditions better than most. This makes us a preferred partner for custom-built heating systems.

Here’s what sets our heaters apart:

1. Tailor-Made for Each Project

Instead of offering off-the-shelf units, Sungov Engineering helps evaluate gas composition, flowrate, ambient temperatures, and pressure conditions to design heaters that fit the site’s exact needs.

2. Robust Quality Standards

Material traceability, welding excellence, and stringent testing procedures ensure that every heater is ready for long-term industrial use.

3. Seamless Integration with Filtration Systems

Since filtration and heating often work together to protect downstream equipment, Sungov’s broad product expertise ensures compatibility and efficient system design.

4. Maintenance-Friendly Design

Accessibility, ease of inspection, and well-placed instrumentation minimize downtime and simplify routine servicing.

5. Trusted Engineering Support

From design to installation to after-sales assistance, Sungov’s experts provide comprehensive guidance throughout the equipment lifecycle.

Choosing the Right Heater for Your Application

Before finalizing a water bath heater, engineers typically evaluate parameters such as:

- Gas flowrate and pressure

- Required outlet temperature

- Minimum ambient temperatures

- Fuel availability for burners

- Space availability at the site

- Type of process fluids and their properties

Discussing these parameters with an experienced manufacturer such as Sungov Engineering ensures that the heater is neither undersized nor oversized as either of them can compromise efficiency.

FAQs: Industrial Indirect Fired Water Bath Heaters

An industrial indirect fired water bath heater transfers heat indirectly using a fire-tube submerged in a water-glycol bath, providing safe, uniform heating for gas and process fluids without direct flame contact.

Indirect gas-fired process heaters isolate the flame from the process fluid, reducing risks of overheating, ignition, and thermal stress while ensuring stable temperature control.

They are commonly used in oil & gas facilities, CGD networks, pressure reduction stations, compressor stations, and petrochemical plants to prevent hydrate formation and maintain consistent gas temperature.

Key benefits include controlled heat transfer, enhanced safety, prevention of freezing and hydrates, low maintenance, and long operational life.

Selection depends on flow rate, operating pressure, outlet temperature, ambient conditions, and fuel type, with expert engineering ensuring optimal sizing and performance.