In industrial settings every second counts and every drop of fluid matters, because it is vital to maintain smooth and efficient flow through pipelines. This is non-negotiable. Whether in oil and gas, petrochemicals, power generation, or water treatment, one small particle or contaminant can throw off an entire system. It can lead to downtime, damage, or costly repairs. That’s exactly where Y Type Strainers come into play. It has a crucial role in ensuring that pipelines run seamlessly.

Let’s look at why these compact yet powerful devices have become indispensable in modern industrial operations.

Understanding Y Type Strainers

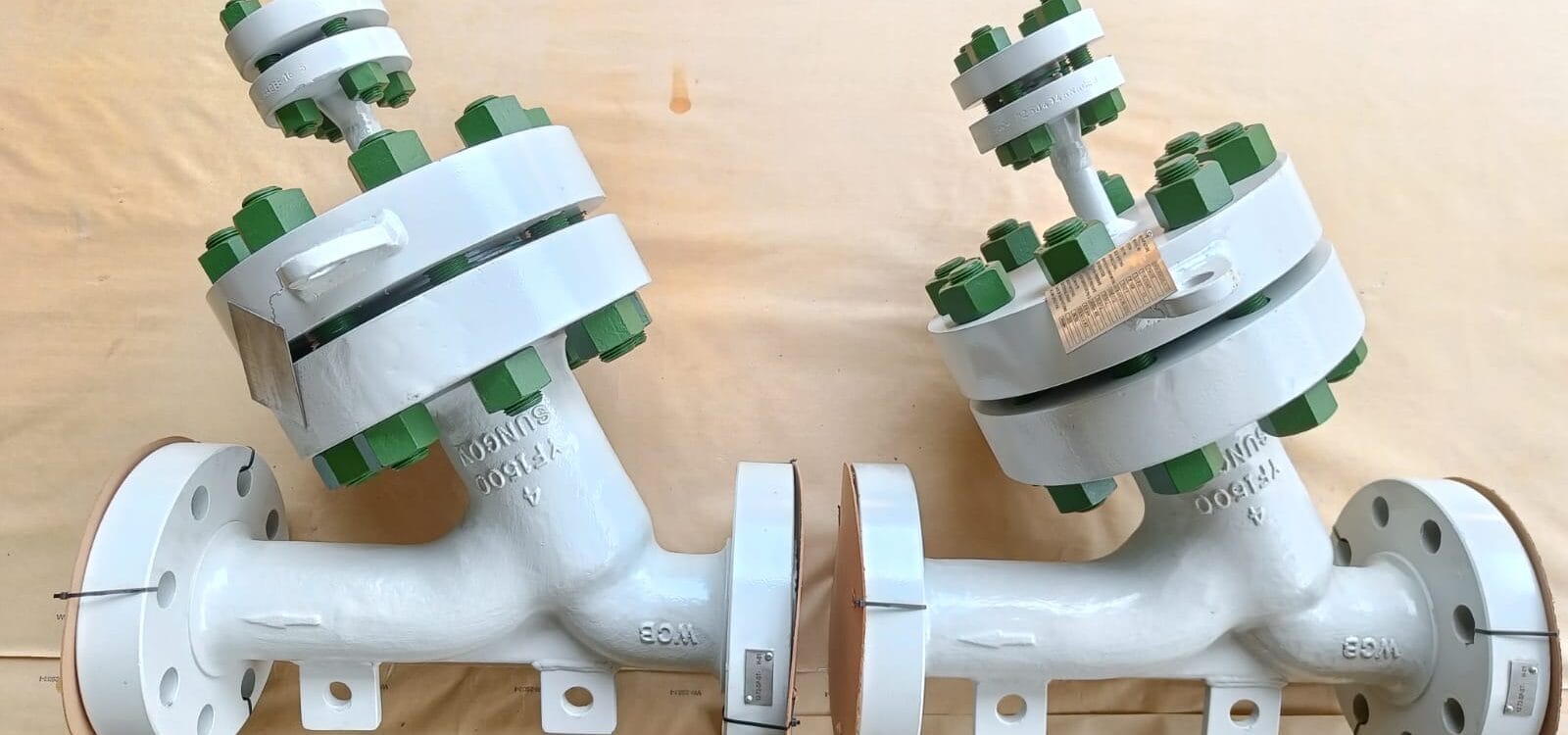

Before exploring their advantages, it makes sense to understand what Y Type Strainers are. As the name suggests, their design resembles the letter “Y.” This shape isn’t just aesthetic — it serves a very practical purpose.

A Y strainer consists of a main body with two branches — one for the flow of the fluid and another housing a mesh or perforated screen that traps unwanted debris. The design allows for minimal pressure drop while efficiently removing particles such as rust, dirt, scale, and other foreign matter from the system.

What makes Y type strainers so popular is their versatility. They can handle both liquid and gas applications and are suitable for horizontal or vertical installations depending on the flow direction. This adaptability makes them an excellent choice for engineers who need reliable filtration with a compact footprint.

Why Strainers in Pipeline Systems Matter

Think of a pipeline as the bloodstream of an industrial plant. Any impurity entering the system can act like a blockage — it can reduce flow, damage valves, erode pumps, and wear out equipment prematurely. That’s why strainers in pipeline systems are not a luxury but a necessity.

By filtering out contaminants before they reach sensitive components, strainers extend equipment life and maintain the desired flow rate and pressure levels. They also help reduce maintenance costs and prevent unplanned shutdowns, which are often far more expensive than planned service intervals.

Among the various types of strainers used — such as basket strainers, T strainers, and duplex strainers — Y type strainers stand out for their combination of efficiency, compactness, and ease of maintenance.

The Design Advantage of Y Type Strainers

The beauty of the Y type strainer lies in its simplicity. Its angled body design directs the flow smoothly, allowing debris to collect in the screen leg without significantly obstructing flow. This means that even when the strainer is working at full capacity, the pressure drop across it remains minimal — a big advantage in systems where maintaining flow velocity is critical.

Moreover, the Y type strainer can be installed in either horizontal or vertical positions, giving engineers flexibility during pipeline design and layout. For example, in vertical installations where the flow is downward, gravity assists in trapping debris — making cleaning even easier.

The strainer cap or plug at the end of the Y leg provides access for cleaning the mesh or replacing the screen without dismantling the entire pipeline. This quick maintenance feature is especially valuable in continuous operations where downtime must be minimized.

Choosing the Right Material: Why Stainless-Steel Strainers Are Ideal

When selecting strainers for industrial use, the material of construction plays a vital role in determining performance, durability, and compatibility with the process fluid. Among all available materials, stainless steel strainers have emerged as a preferred choice across industries.

Stainless steel offers superior resistance to corrosion, high temperatures, and pressure — all of which are common in industrial environments. Whether the fluid that is filtered is water, oil, steam, or chemical, stainless steel maintains structural integrity and prevents contamination.

Moreover, stainless steel strainers have a longer lifespan and require less frequent replacement compared to cast iron or carbon steel alternatives. This makes them not only reliable but also cost-effective in the long run. For industries like oil and gas or power generation, where pipeline safety and reliability are paramount, stainless steel becomes the material of choice.

Key Benefits of Y Type Strainers

Let’s look at some of the main benefits that make Y type strainers essential for efficient pipeline operation:

Effective Particle Removal:

Y type strainers efficiently remove solid impurities from liquids and gases, protecting downstream components like pumps, valves, compressors, and flow meters.

Compact and Versatile Design:

Their Y-shaped structure takes up minimal space, making them suitable for installations where space is limited.

Low Pressure Drop:

The design minimizes flow resistance, allowing for smooth operation and maintaining energy efficiency in the system.

Ease of Maintenance:

The blow-off connection or plug allows operators to clean the strainer without removing it from the line — a big advantage in systems that run continuously.

Durability:

Especially when made from stainless steel, Y type strainers offer long service life and high resistance to wear, corrosion, and temperature fluctuations.

Wide Application Range:

These strainers can be used in various systems — from water pipelines and fuel gas systems to steam lines and compressed air systems.

Applications Across Industries

The versatility of Y type strainers makes them suitable for a wide range of industries and applications:

Oil and Gas: Protecting compressors, pumps, and burners from contamination in fuel gas lines.

Power Plants: Filtering debris from steam and condensate lines to prevent turbine damage.

Chemical and Petrochemical Plants: Ensuring clean process fluids to maintain product purity.

Water Treatment Plants: Removing suspended solids before reaching sensitive equipment.

HVAC Systems: Filtering chilled water or cooling fluids to maintain system efficiency.

Maintenance and Best Practices

Even the most durable stainless-steel strainers need regular maintenance to perform optimally. Over time, debris buildup can reduce flow or increase pressure drop. The frequency of cleaning depends on the application and the level of impurities in the system.

Many Y type strainers come equipped with a drain plug that can be replaced with a blow-off valve for easier cleaning. In high-pressure systems, using an isolation valve before the strainer can make maintenance safer and more convenient.

It’s also important to monitor the pressure differential across the strainer. A sudden increase in pressure drop indicates that the screen needs cleaning or replacement. Keeping spare screens on hand can further reduce downtime during maintenance.

Sustainability and Efficiency Go Hand-in-Hand

In today’s world, where sustainability is becoming a key focus, components that reduce waste and extend equipment life contribute directly to energy efficiency and environmental responsibility.

By preventing equipment failure and maintaining consistent flow rates, Y type strainers help industries reduce energy consumption, minimize process interruptions, and extend the operational lifespan of key assets. Their reusable, long-lasting stainless-steel construction also means fewer replacements — aligning with sustainable engineering practices.

At Sungov Engineering, we specialize in designing and manufacturing robust filtration solutions, including precision-engineered Y type strainers, that ensure smooth, uninterrupted flow across industrial pipelines. Because when your flow is efficient, your entire operation performs at its best.

FAQs About Y Type Strainers for Pipeline Systems

A Y type strainer is a filtration device shaped like the letter “Y” that removes debris from pipelines. It works by directing fluid through a mesh or perforated screen that traps particles such as rust, scale, and dirt. This helps maintain smooth flow and protects downstream equipment in both liquid and gas applications.

Strainers in pipeline systems are essential because they filter out impurities before they reach pumps, valves, turbines, and other sensitive components. By preventing blockages, equipment damage, and pressure drop issues, strainers help reduce maintenance costs and avoid unplanned shutdowns.

Stainless steel strainers offer superior corrosion resistance, high-temperature durability, and long service life. They are ideal for industrial applications involving water, steam, oil, and chemicals. Their strength and longevity make them more cost-effective than cast iron or carbon steel strainers.

Y type strainers are used in industries such as oil and gas, petrochemicals, power generation, water treatment, and HVAC systems. They are installed in pipelines in regions like the UAE and India to protect equipment, maintain flow efficiency, and ensure clean process fluids.

The cleaning frequency depends on the fluid quality and operating environment. In general, Y type strainers should be inspected regularly and cleaned when pressure drop increases, indicating debris buildup. Many units include a blow-off connection to simplify maintenance without removing the strainer from the line.